6-Week Custom Guitar & Bass Build in Paris

Description

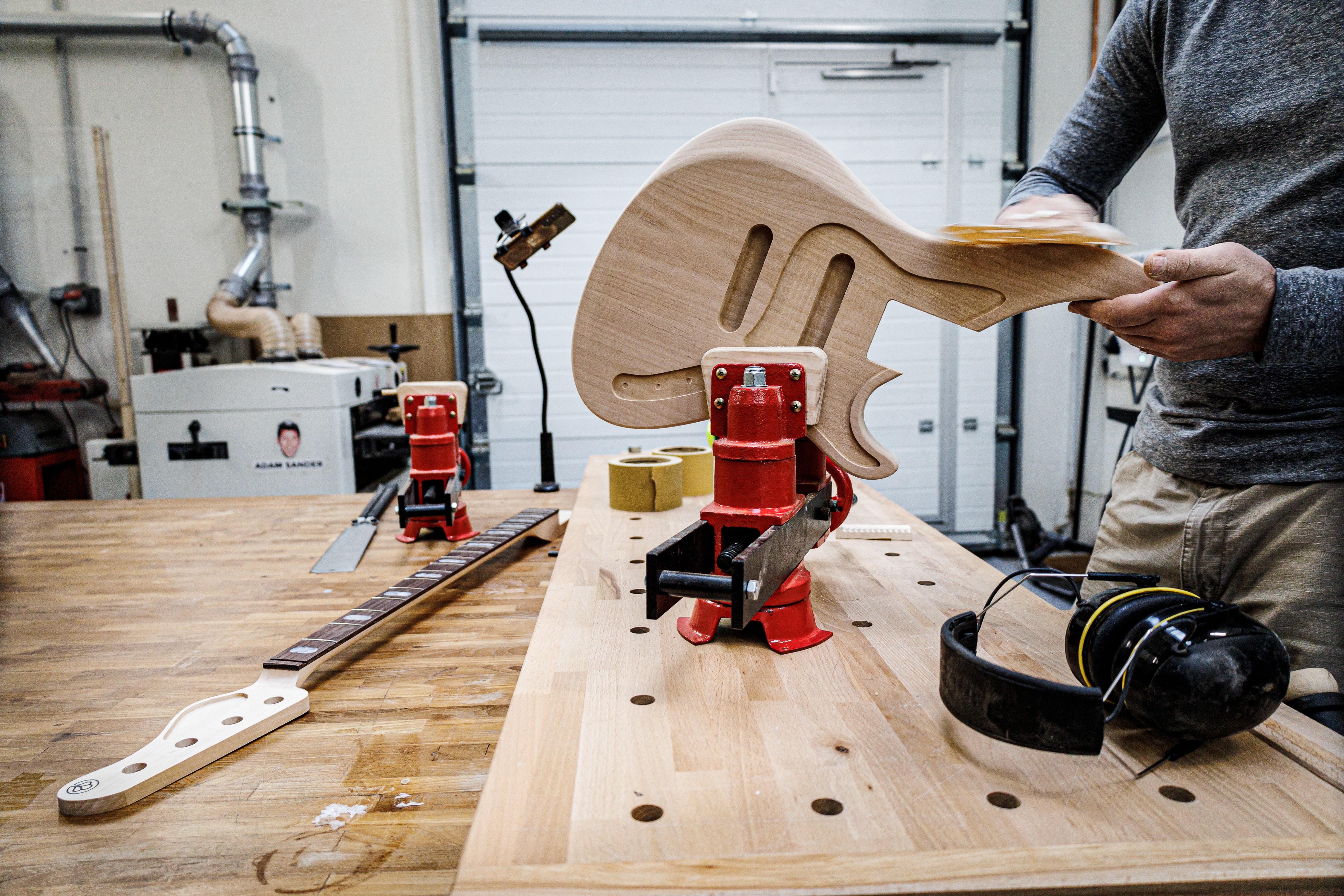

This intensive 6-week course is the ultimate custom lutherie experience. Design your own electric guitar or bass from scratch — from CAD modeling to CNC prep, advanced carving, custom fretwork, complex finishing, and complete professional setup. Work one-on-one in a modern Paris workshop and create a truly unique instrument built to your specifications. Perfect for serious hobbyists, builders, and players ready to push their craft to the next level.

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

Build you own design

6-Week Custom Build Experience

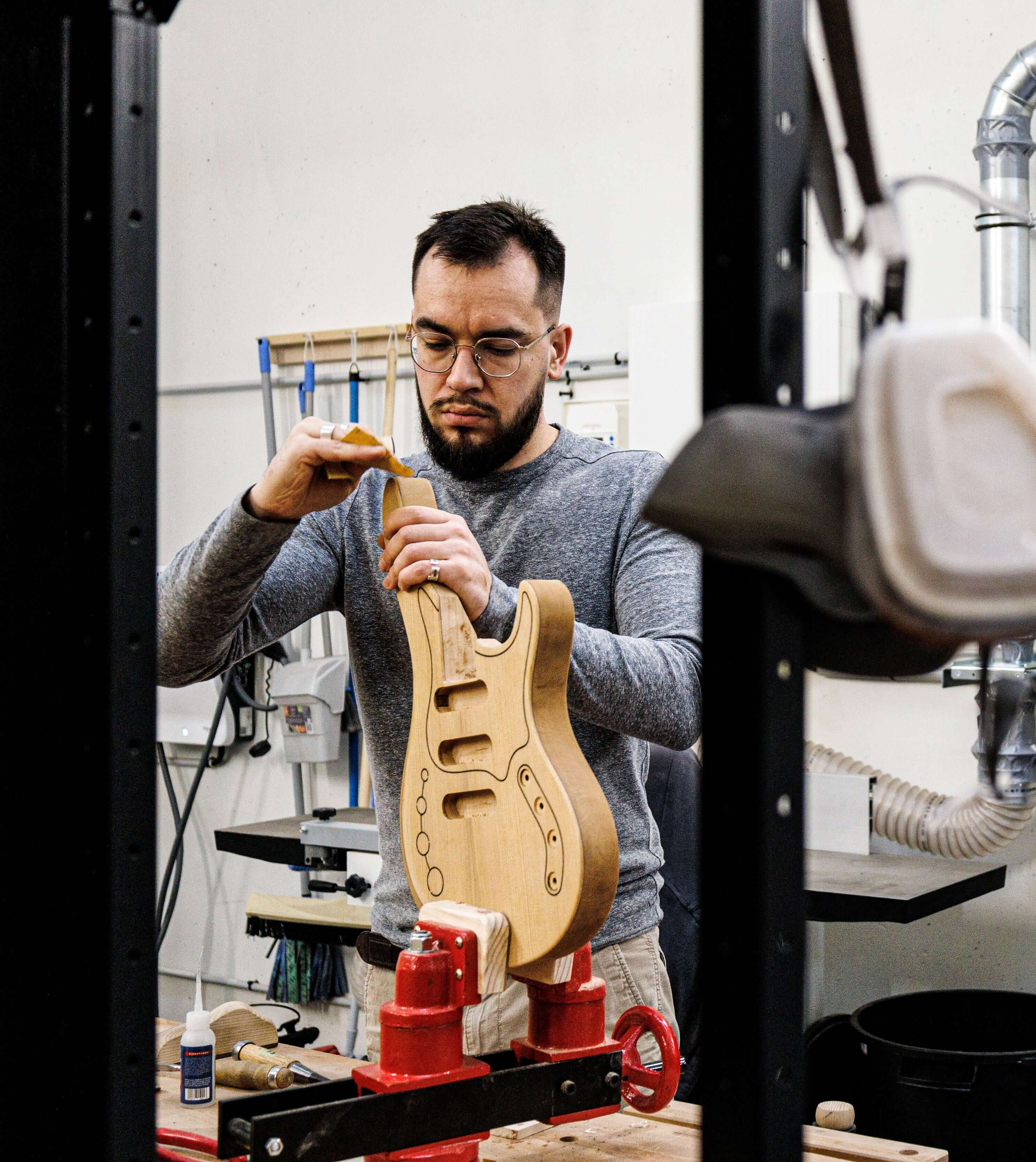

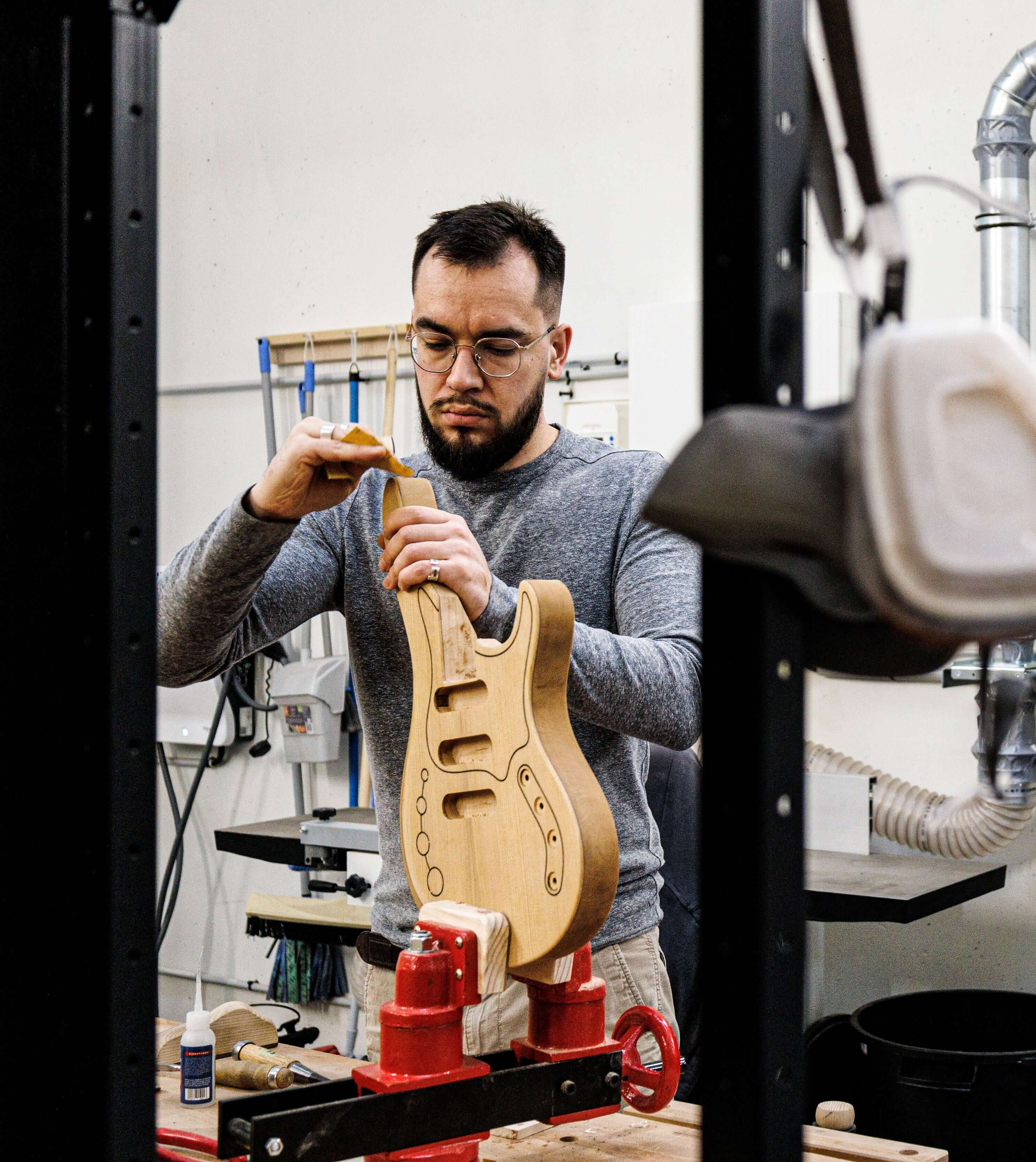

This flagship 6-week course is the most comprehensive and customizable program at the Belforti Lutherie School — a unique opportunity to design, build, and complete an entirely original electric guitar or bass from scratch. It’s not about following a pre-existing plan or assembling stock parts: it’s about creating something deeply personal, shaped by your aesthetic, ergonomic, and tonal goals.

From day one, you take creative control. With guidance at every step, you’ll design your own instrument — from its silhouette and scale length to pickup layout, neck feel, fretboard material, hardware color, and visual identity. You’ll explore your design through 2D/3D modeling, translating ideas into clean, functional geometry. No two students build the same instrument — and that’s exactly the point.

You’ll work through the full process using both traditional lutherie techniques and modern production tools, including CNC-assisted cutting, advanced fretwork, multi-stage finishing, and full electronics setup. This course is for those ready to explore the craft in depth, to push the limits of what they can create, and to walk away with a truly professional-grade instrument — designed, built, and tuned by their own hands.

Whether you’re chasing a personal dream build, refining your skill for future work, or laying the foundation for your own design language as a luthier, the Custom Experience is where creativity meets precision.

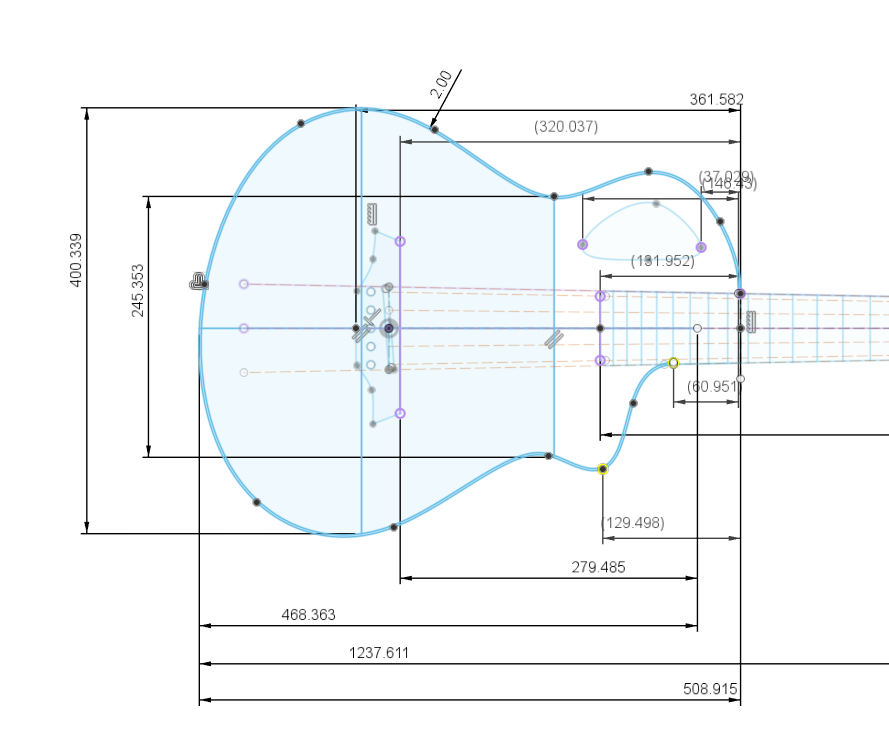

One-to-One Custom Design

Your journey begins with a clean sheet. You'll work directly with the instructor to develop your own guitar or bass design — scale length, pickup layout, neck profile, hardware configuration, aesthetics, and ergonomics. You’ll model your instrument in Fusion 360, produce full technical drawings, and prepare CAM-ready files. This phase defines your build’s identity — balancing function, originality, and feasibility.

Complex Fretting, Finishing & Structural Detail

Work with hidden fret tangs, bound fretboards, custom radius profiles, and inlay techniques. Choose from open-pore finishes, translucent stains, multi-stage PU or oil-based treatments. This is your space to experiment: tapered necks, compound radii, engraved plates, even matching electronics plates or headplates. We'll guide you through professional-grade results while helping you develop your visual language as a builder.

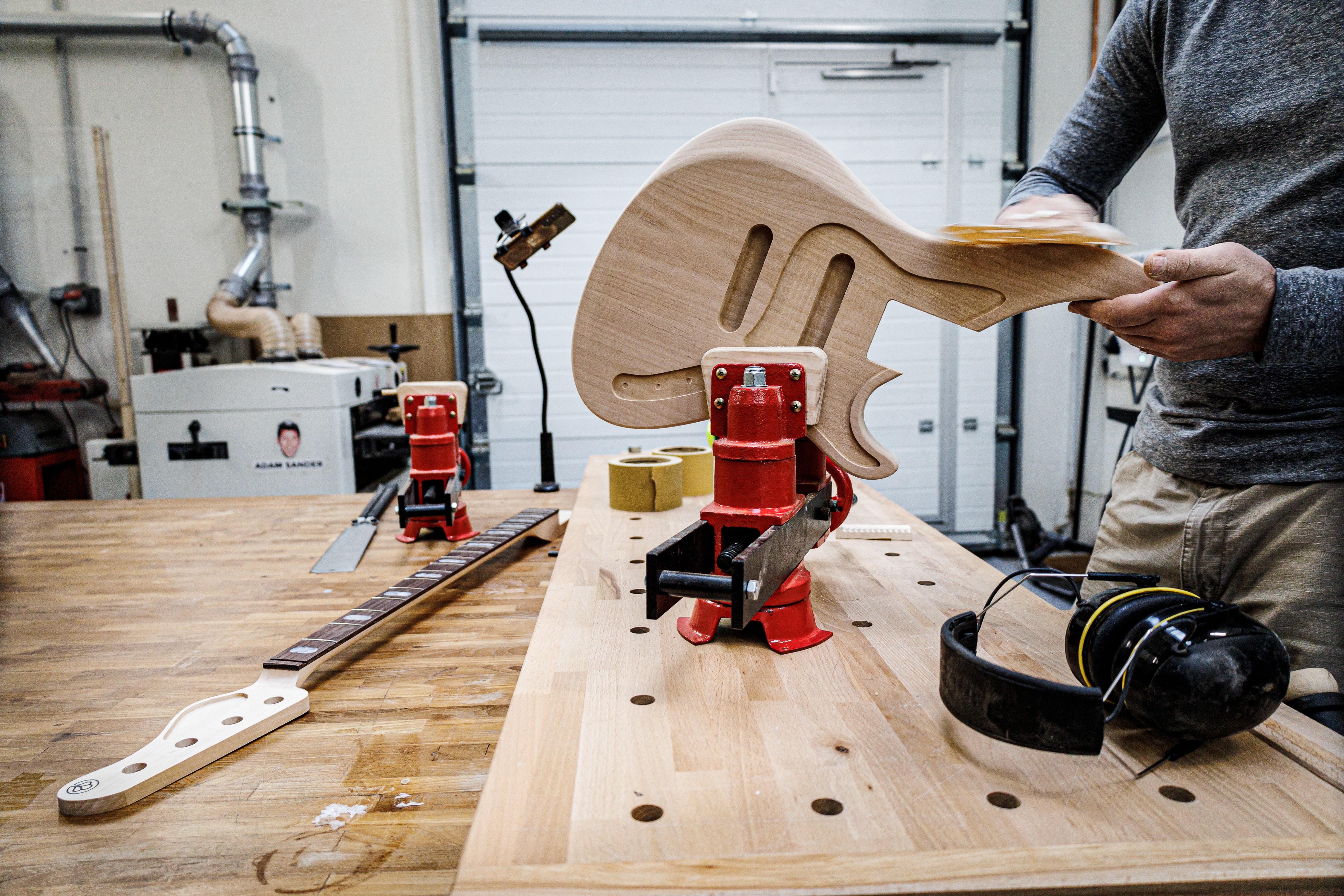

Advanced Woodworking & Body Shaping

From the CNC-rough cut to final hand shaping, you’ll carve, route, and refine every part of your instrument. This includes complex neck joints, body contours, laminated tops, custom inlays, headstock shaping, and edge transitions. You’ll use jigs, templates, rasps, spokeshaves, routers, and drills — learning how to blend machine precision with the nuance of fine handcraft.

Electronics, Assembly & Final Setup

From soldering intricate wiring schemes to aligning bridges and nut slots, the last phase brings the instrument to life. You’ll assemble and wire everything — whether it's a clean classic circuit or a multi-pickup custom switch layout. Truss rod adjustment, nut shaping, stringing, fret dressing, and full setup bring the guitar or bass to playing perfection.

Beyond the Basics

Production Techniques, CNC & Fine Lutherie

This isn’t just a build — it’s a full-lutherie experience. You’ll work through a professional design-to-shop pipeline, gaining insight into hybrid workflows that blend CNC accuracy with hand-finishing precision. Whether you’re carving a comfort bevel, designing a multi-pickup circuit, or creating a flawless neck join, every detail is shaped with care — and guided with critical feedback.

Advanced Wood Acoustic & Mechanical Analysis

One of the defining features of the Belforti 6-Week Custom Experience is the deep dive into the mechanical and acoustic behavior of the woods you work with — not just their aesthetics. Before cutting or shaping begins, you'll assess each blank through guided testing, resonance mapping, and structural observation. This process teaches you how to "read" a piece of wood — not just by weight or grain, but by how it wants to vibrate, flex, and interact with the rest of the instrument.

Using documented tap testing, spectral listening, and reference grading from scientific research, we examine how variables like grain orientation, density, elasticity, and internal damping contribute to tone shaping — and how to pair materials with design goals.

This isn't guesswork — it's an informed approach to choosing your components with intent.

You’ll leave with an understanding of:

- how wood stiffness and damping affect articulation, response, and sustain

- how to identify structural weak points before shaping

- how to use mass and tension balance to guide chambering or contouring

- how finishing, glue lines, and carving influence acoustic behavior in solidbody design

This layer of analysis adds a level of control and decision-making that sets your custom build apart — and connects lutherie to the science of resonance and response.

What You'll Learn

Throughout the course, you’ll acquire professional-level techniques, including:

- Custom CAD modeling & CAM file prep (Fusion 360)

- CNC logic and setup for necks, pockets, tuner holes, and cavities

- Routing from scratch using workshop jigs

- Neck construction: scarf joints, multi-piece necks, truss rod installs

- Complex fretting: bound boards, hidden tangs, compound radii

- Design and execution of custom inlays

- Top carving, drop-tops, laminated bodies

- Multi-stage finishing with stains, sealers, and clear coats

- Electronics wiring from classic to complex

- Full assembly and setup for professional performance

What You’ll Leave With

- A completely custom-built, pro-grade electric guitar or bass

- Your own digital design files (CAD, CAM, DXF, SVG, PDF)

- Production-ready templates for future builds

- Deep understanding of wood behavior, construction strategy, and geometry

- Advanced finishing, fretwork, and soldering skill

- A personal design that reflects your voice, not just your hand

- Confidence and workflow for pursuing independent lutherie or deeper study

Week by Week Program

Week 1

- One-on-one design briefing: shape, scale, tone, ergonomics

- Fusion 360 CAD sketching and 3D modeling of body, neck, and hardware layout

- CAM preparation and CNC machining: tuner holes, neck pocket, truss channel

- Wood selection and acoustic/mechanical testing (tap tone, stiffness, grain behavior)

- Truss rod installation and fingerboard gluing

- Body and headstock outline shaping

- Neck blank prep: scarf joints, rough carving starts

Week 2

- Full neck carving: back contour, heel, headstock transition

- Inlay design and installation (dot, logo, or symbol motif)

- Binding or edge treatments (if applicable)

- Bridge drilling, hardware dry-fit

- Fret slotting, pressing or hammering frets, leveling, crowning & polishing

- Ergonomic contouring: belly cut, forearm bevel, custom edge shaping

- Final sanding and surface prep for finish

Week 3

- Multi-stage finishing: stain work, grain fill (if required), clear coats

- Satin, gloss or oil finishes depending on project

- Cure/dry time, sanding, buffing, logo application

- Final assembly: tuners, bridge, electronics, strap buttons

- Wiring: grounding, shielding, custom or traditional circuit

- Setup: truss rod adjustment, nut slotting, action, intonation, pickup height

- Playing test, final tweaks, pro photography & course completion debrief

Course Details

Price

5000€

*+Optional Belforti Tool Kit

3D Printed Neck Rest Offered

Who it’s for

This program is ideal for:

- Passionate builders who want full control of every design and construction choice

- Players seeking to bring a dream instrument to life, from concept to tone

- Serious students preparing to launch their own builds or apply for apprenticeships

- Those who’ve completed the 3-week course or already have solid workshop experience

This is not a beginner course. You must be comfortable with tools, materials, and multi-day focused work.

Location

Belforti Instruments Manufacture

Greater Paris area

41bis rue des Mazurières - 92500 Rueil-Malmaison

Breaks & Lunch

- 1-hour lunch break daily

- Coffee/tea and water available

- Bring your own lunch or use nearby cafés

What’s Provided

- All wood blanks, templates, and hardware

- Use of CNC for specific stages (neck pocket, truss channel, tuner holes)

- Premium lutherie tools, jigs, finishing equipment

- Fusion 360 support & export formats

- Expert guidance for every phase

- Coffee, tea, and shared breaks

- Studio-quality photos of your completed instrument

What to Bring

- Personal drawings, sketches, references (optional)

- Your own pickups, bridge, tuners, or electronics (if pre-approved)

- Workshop-safe clothing and closed-toe shoes

- Hearing protection

- Your personal tool kit (strongly recommended). Otherwise, a refundable deposit applies to borrow house tools.

Duration & Group Size

- Duration: 6 weeks

- Daily Hours: 9:30 AM – 5:30 PM (approx)

- Max 2 participants per session

- Full-time, hands-on format

Disclaimer

This course allows complete creative freedom within functional limits — but successful completion depends on your effort, discipline, and attention to detail. Advanced builds are by nature slower and less predictable. Every student finishes with a playable instrument, but not all concepts can be completed to perfection in the timeframe, especially if new techniques are pushed beyond your current skill level.

We will help you balance ambition and realism so that your final build is strong, musical, and distinctly yours.

FAQs

Can I bring my own design or start from an existing one?

Yes — you can start from scratch or refine an idea you already have. We’ll help translate it into production-ready geometry and logic.

Do I need Fusion 360 experience?

No, but it helps. You’ll be guided through the entire modeling and CAM process, step-by-step. Basic comfort with computers and design software is essential.

Can I use exotic woods or unusual hardware?

Yes — within reason. All materials and parts must be confirmed in advance to ensure compatibility and workflow safety.

Will I use the CNC machine myself?

No, but you’ll be present for toolpath preparation, machine setup, and live demos. This is not a CNC operator course, but you’ll learn how CNC fits into modern custom work.

Can I build something radically shaped or experimental?

Possibly — but we’ll assess feasibility in the design phase. The goal is an artistic but buildable instrument. We won’t greenlight designs that are structurally unsound or unworkable within 6 weeks.

Will I be ready to build professionally after this course?

This course gives you strong foundations, but true professional readiness takes time, repetition, and real-world practice. You’ll leave with clarity, workflow, and a finished portfolio piece — but your growth continues beyond these 6 weeks.