Electric Guitar Design Course in Fusion 360

Description

Design your own electric guitar or bass from scratch — digitally and professionally. In this 3-day course, you’ll create a full 2D and 3D model in Fusion 360, ready for CNC or prototyping. You’ll explore proportion, balance, hardware layout, and build constraints — all with luthier guidance and practical tips for routing, jig design, and manufacturing logic.

You leave with a fully editable CAD file and the blueprints to bring your idea to life.

Requirements: Laptop with Fusion 360 (free personal license), mouse, and general computer proficiency.

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

3-Day Instrument Design in Fusion 360

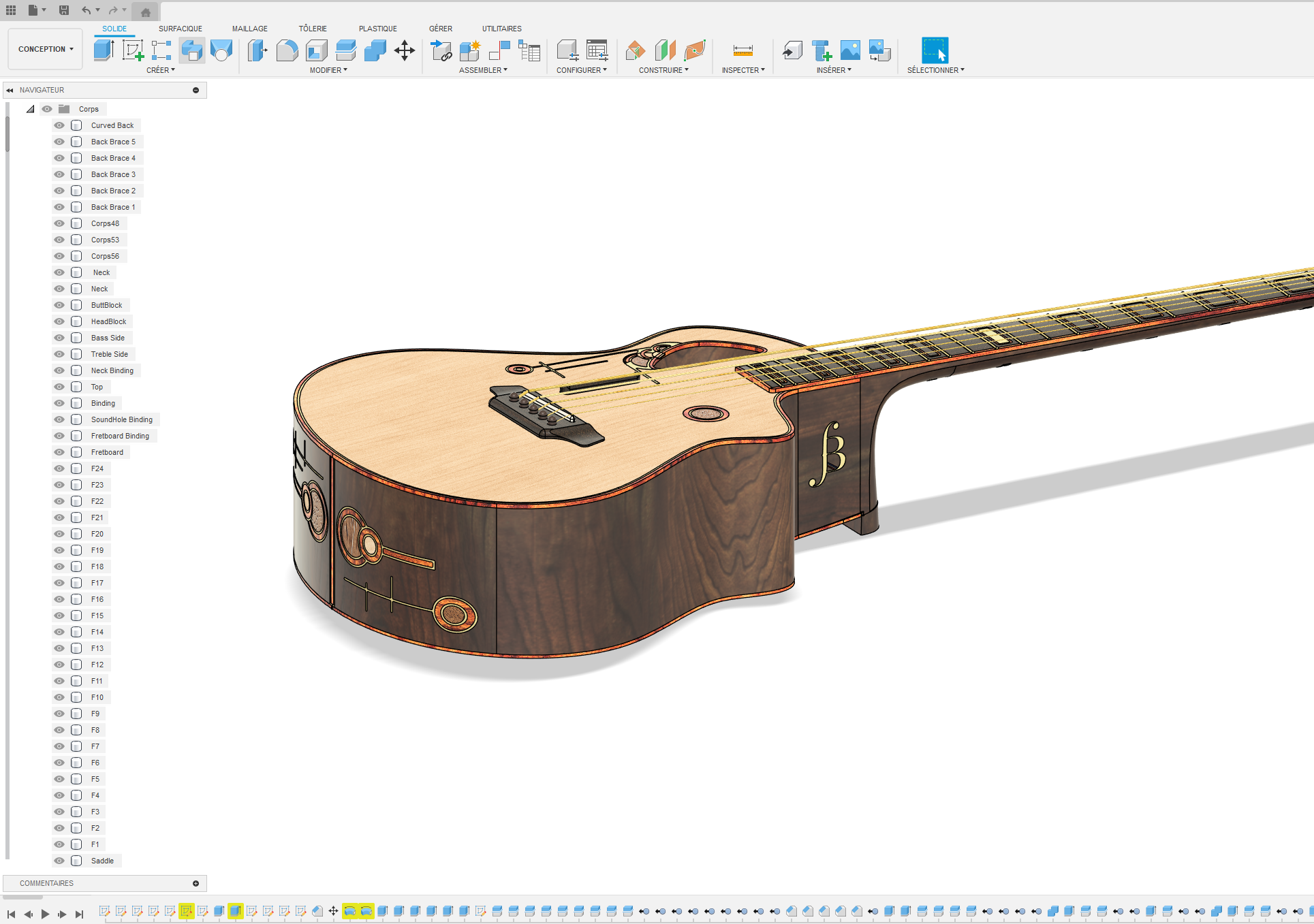

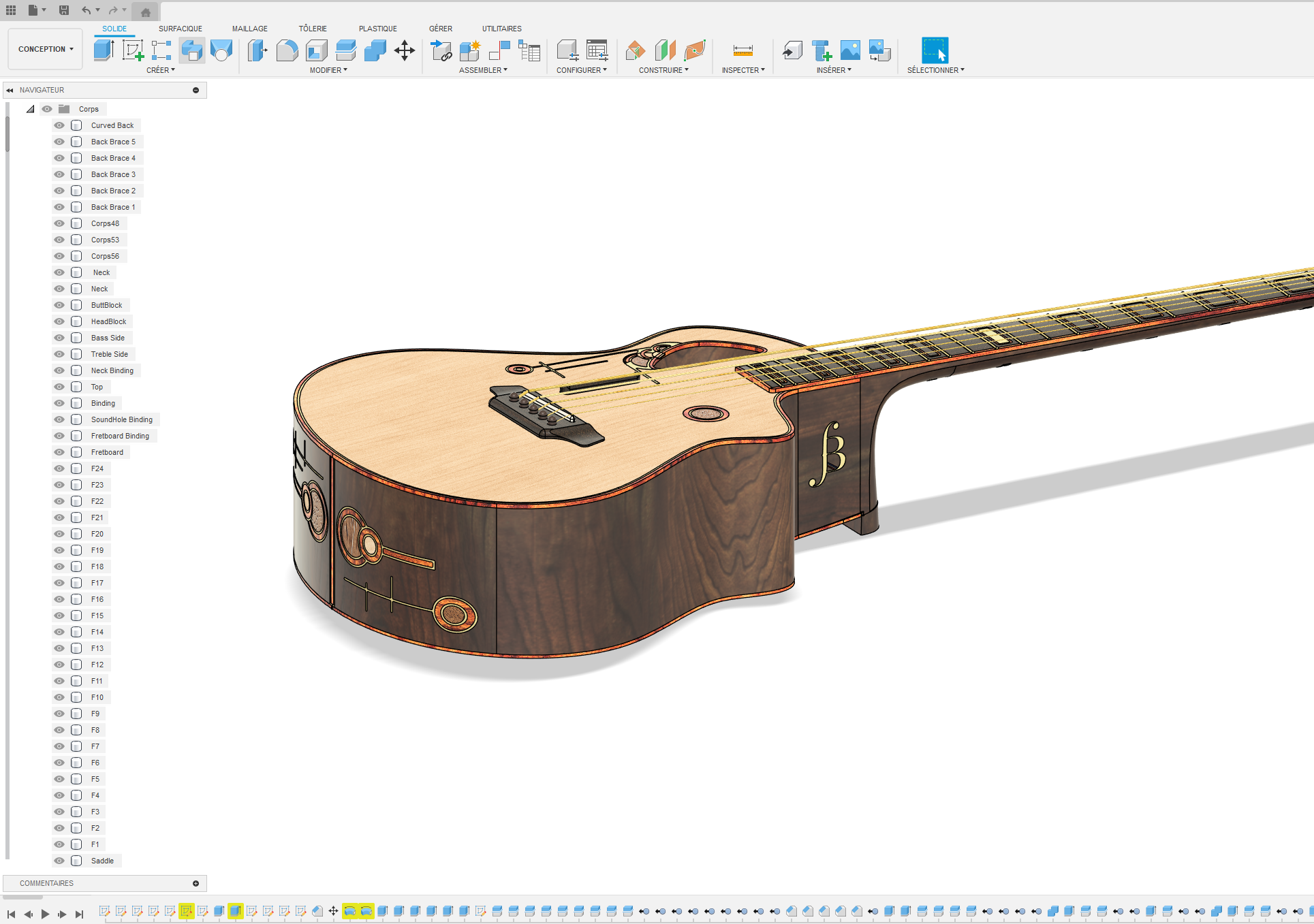

This 3-day workshop is a deep dive into the design foundations of electric guitar and bass construction — using the industry-standard Fusion 360 CAD platform. Whether you're dreaming of building your own instrument someday or refining your prototyping skills, this course teaches how to digitally model a playable, manufacturable instrument from scratch.

In just three days, you'll design a full-scale 2D and 3D guitar or bass model with clean parametric geometry, exportable files, and workshop-ready details. You’ll learn the ergonomic, mechanical, and practical rules behind modern instrument design — with close one-to-one support throughout. No prior lutherie experience required, but computer confidence is essential.

Design Principles & Ergonomics

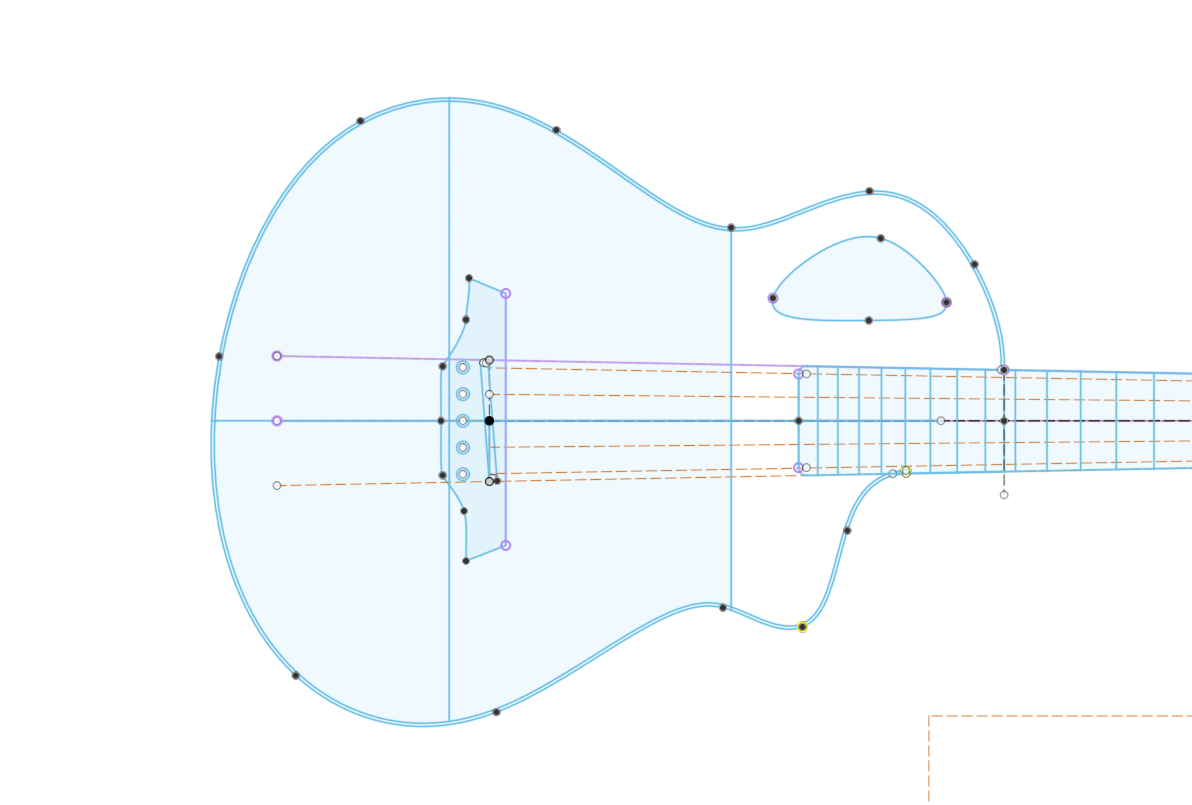

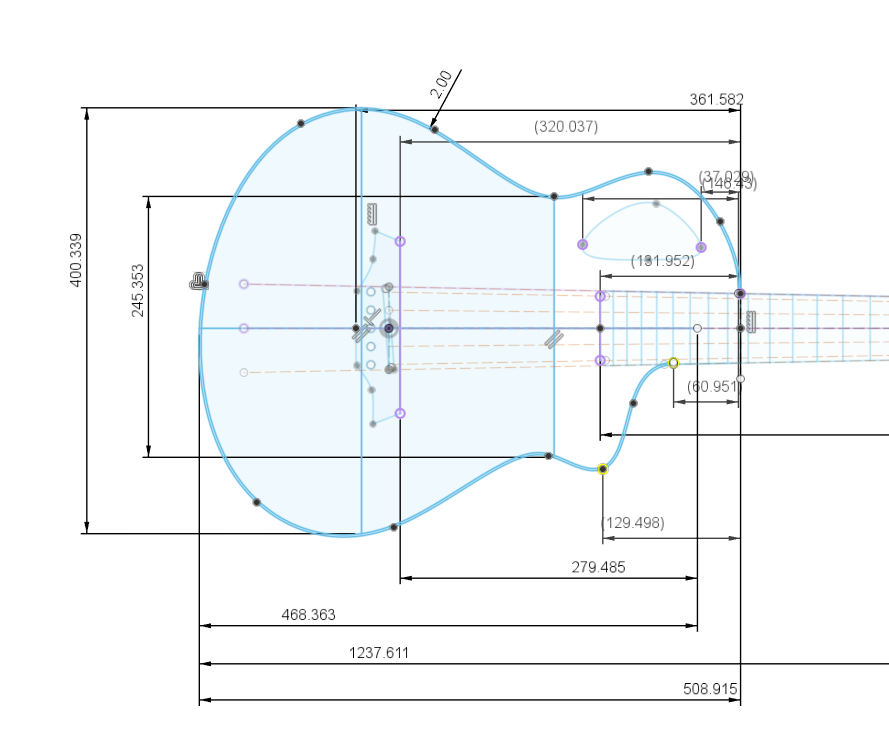

We begin with the fundamentals of what makes a playable, balanced instrument: scale length, bridge placement, neck angle, body mass, and playing posture. You’ll learn how to sketch your body outline using ergonomic guides, define your string path, and center your hardware layout around real-world parts. This isn’t abstract concept work — it’s a grounded, technical approach to turning ideas into reality.

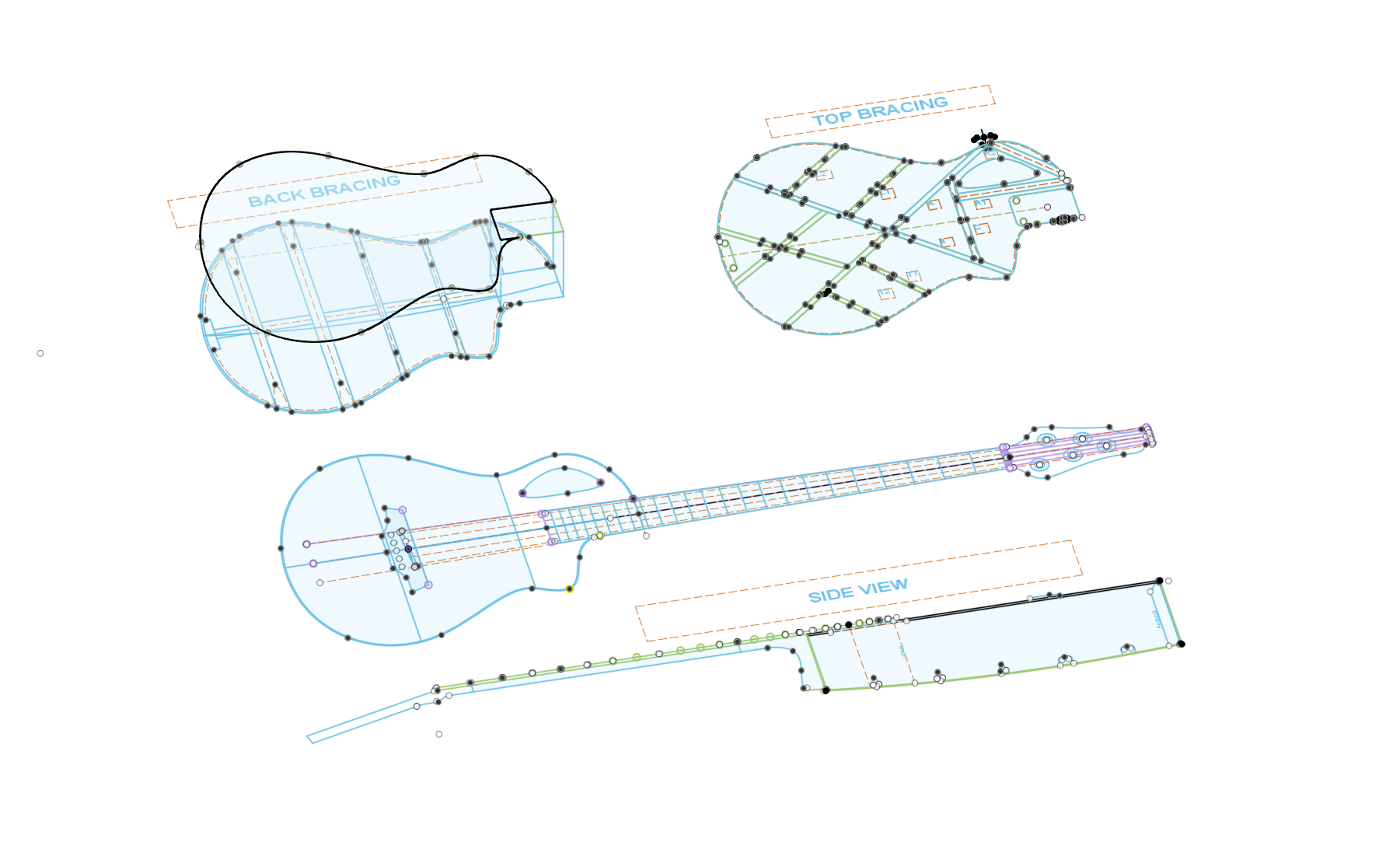

From Sketch to 3D Assembly

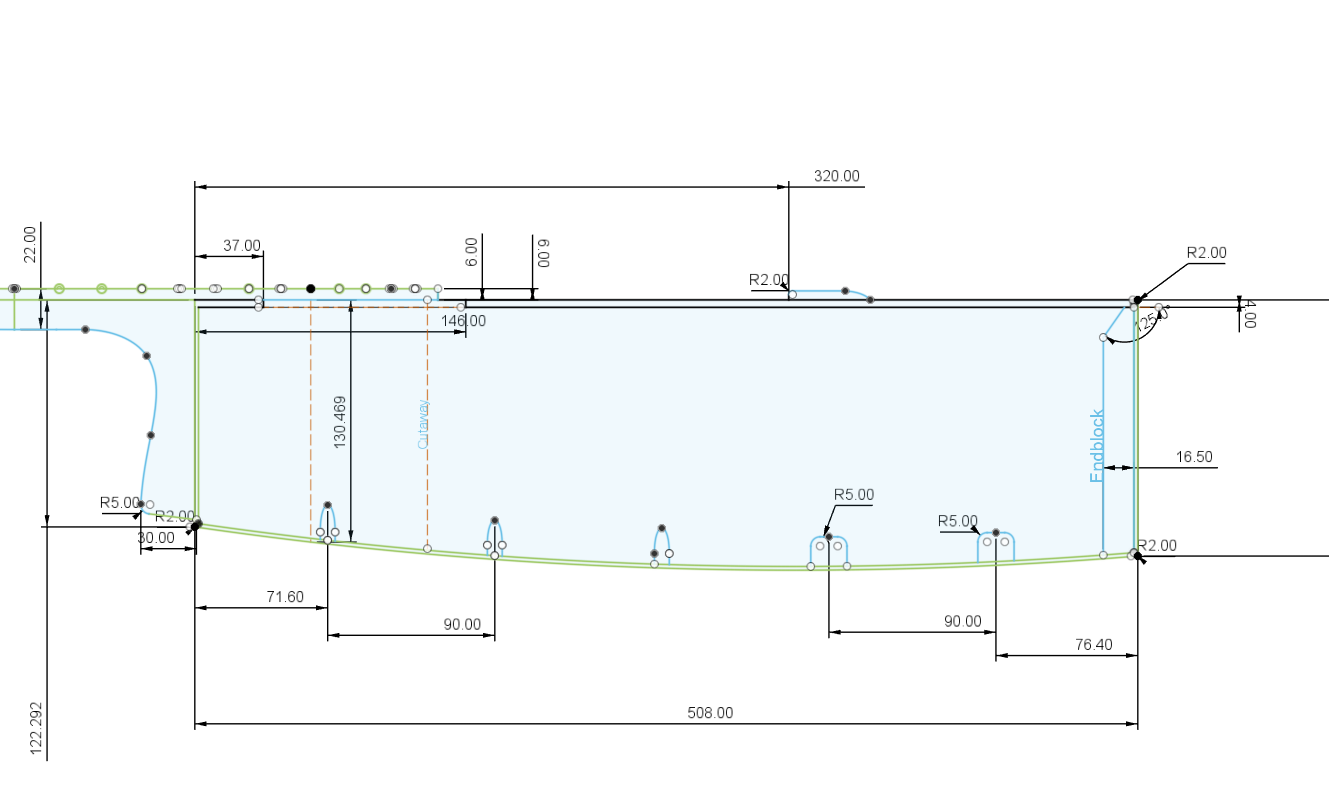

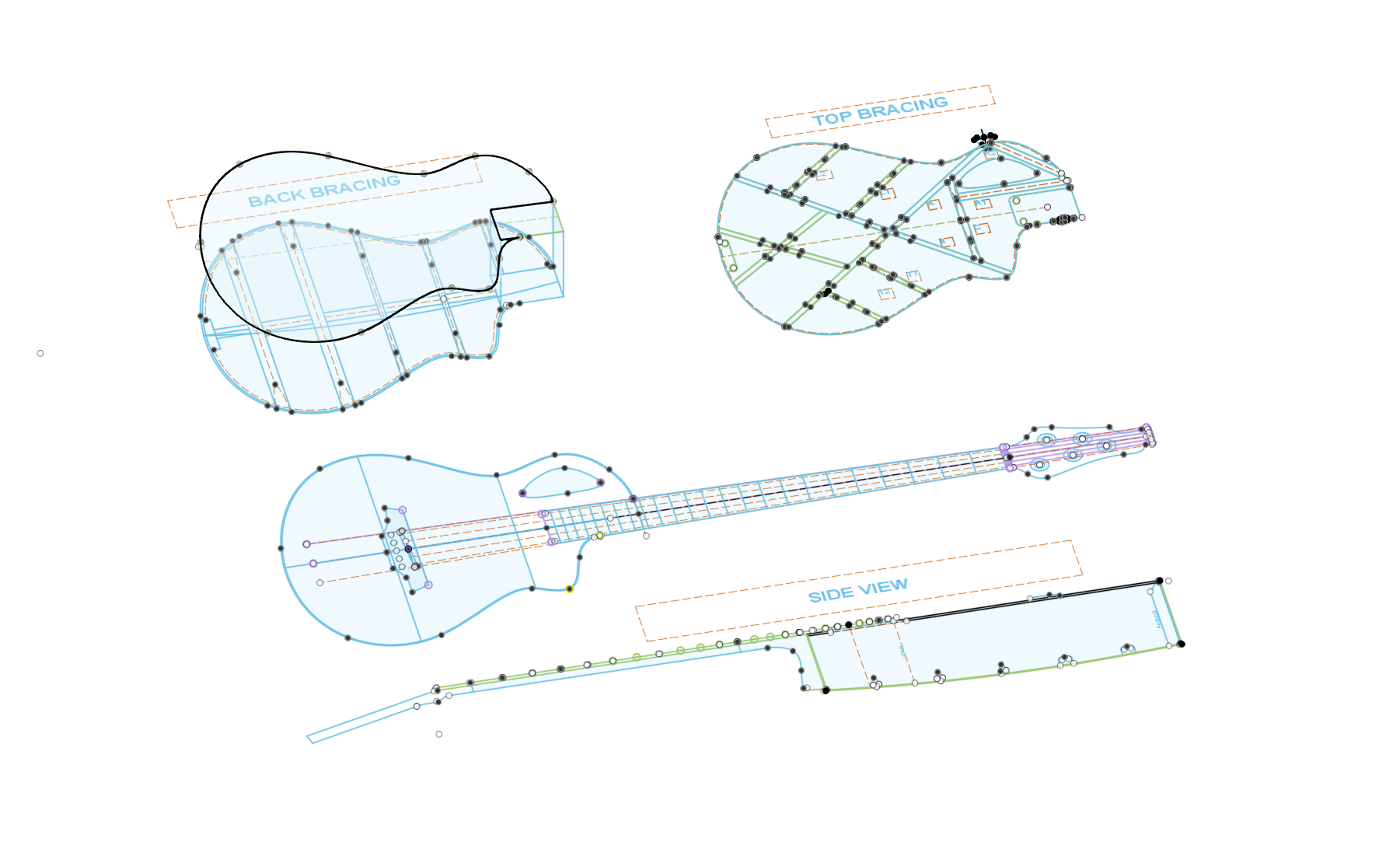

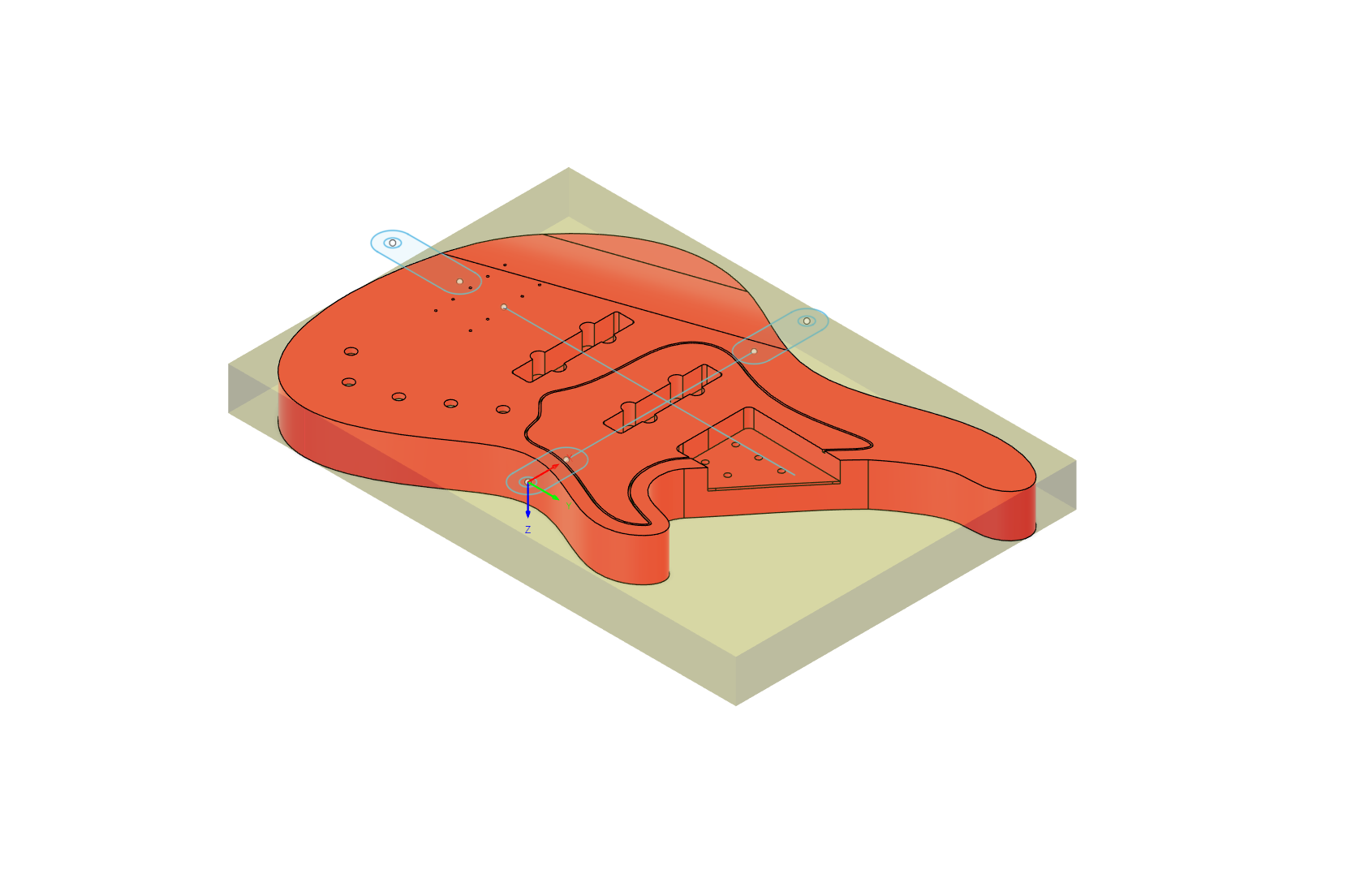

Next, you'll extrude your sketches into realistic 3D parts — body, neck, fingerboard — and learn to align and join them properly. We cover neck pocket fitting, truss rod cavity placement, control cavities, and part visibility toggling. By the end of the session, your instrument will exist as a full 3D model, complete with mounting holes, part depths, and printable views.

Fusion 360 Workflow & 2D Sketching

Once your proportions are right, we move into Fusion 360's design environment. You'll build a 2D parametric sketch of your body and neck, define critical dimensions, and generate clean geometry for cut paths and templates. We’ll cover key tools like constraints, mirroring, user parameters, and modular design blocks — all tailored to luthier workflow and CNC/CAM logic.

Manufacturing Logic & Export

With the instrument fully modeled, we wrap with a practical look at production: routing templates, 1:1 PDF exports, STL and DXF for CNC or laser cutting, and how to break your model into workshop-friendly assets. We’ll also touch on common mistakes that cause builds to fail — like missed tolerances or flawed geometry — and how to check your model for manufacturing viability.

What You'll Learn

Throughout the course, you’ll acquire professional-level techniques, including:

- Complete Instrument Design from scratch on Fusion 360

- Proportions, silhouette and visual hierarchy

- Ergonomic considerations (weight, balance, access)

- Anatomy of a modern electric instrument

- Introduction to CAD for lutherie (Fusion 360 overview)

- Converting an idea into a usable design

- Template Design

What You’ll Leave With

- A complete 2D and 3D electric guitar or bass design (Fusion 360 file)

- Blueprint with accurate geometry, layout, and drilling points

- Production-ready exports (DXF, PDF, STL or SVG) for routing or laser cutting

- Understanding of neck scale, bridge alignment, string spacing, and ergonomics

- Fusion 360 project workflow, sketch discipline, and clean parametric habits

- Confidence to start prototyping or building with precision

Day by Day Program

Day 1

- Overview of electric guitar & bass design language

- Proportions, silhouette analysis, weight distribution

- Anatomy of a modern instrument (functional vs aesthetic constraints)

- Study of iconic models: what works, what doesn’t, why

- Sketching fundamentals: line quality, gesture, reference points

- Practical session: drawing basic body templates

Day 2

- Player interaction: balance, contouring, access, forearm + belly cuts

- Neck geometry (nut width, thickness, radius, profile)

- Scale length & its implications (bridge placement, tension, pickup spacing)

- Bridge, hardware, and control layout mapping

- Practical session: refining sketches into proportionally accurate templates

- Introduction to CAD (Fusion 360): interface, sketch workspace, constraints

Day 3

- Converting hand drawings into CAD sketches (guided step-by-step)

- Creating a clean 2D digital template

- Understanding CNC constraints and manufacturing considerations

- Material selection principles: weight, workability, aesthetics

- Final project: each participant leaves with a coherent design template

- Group review and design critique session (professional feedback)

Course Details

Price

700€

3D Printed Neck Rest Offered

Who it’s for

This course is designed for:

- Musicians who want to understand how instruments are conceived and engineered

- Aspiring luthiers seeking a solid foundation in modern design and CAD

- Industrial designers & creatives interested in translating ideas into functional instruments

- Builders who want to move from sketches to clean, production-ready files

- Enthusiasts who enjoy experimenting with shapes, ergonomics, and visual identity

No prior drawing or CAD experience is required—just curiosity, focus, and comfort using a computer.

Location

Belforti Instruments Manufacture

Greater Paris area

41bis rue des Mazurières - 92500 Rueil-Malmaison

Breaks & Lunch

- 1-hour lunch break daily

- Coffee/tea and water available

- Bring your own lunch or use nearby cafés

What’s Provided

- 1:1 coaching and design review throughout the course

- Example files and ergonomic templates to start from

- Standard bridge and pickup measurements for compatibility

- A complete Fusion 360 workflow adapted to lutherie

- PDF and DXF export support

- Workspace, Wi-Fi, and projection screen with live demo view

- Coffee, tea, and light refreshments during the day

What to Bring

To get the most out of the workshop, you must bring:

- A laptop capable of running Fusion 360 smoothly

- A mouse (mandatory — CAD work is too slow on trackpads)

- A Fusion 360 Free License installed and activated before the course

- A basic level of computer ease (navigating apps, using shortcuts, file management)

All other materials (references, templates, examples) are provided during the workshop.

Duration & Group Size

- 3 days (≈21 hours)

- 3 to 4 participants for close supervision

Intensive, hands-on format

Disclaimer

This course is focused on instrument design, not fabrication. While you'll leave with a complete digital model suitable for prototyping or building, no physical instrument is made during the workshop. The quality and usability of your design will depend on your ability to follow the process, work cleanly in Fusion 360, and stay within realistic build parameters. If you come with an unconventional concept, we’ll help refine it — but we can’t guarantee that every idea will result in a viable or buildable instrument.

Participants must be comfortable working with a computer, navigating software interfaces, and using a mouse. This is a technical design course, not an intro to basic digital tools.

FAQs

Do I need experience with Fusion 360?

No prior CAD experience is required — but you must be comfortable with computers. A working knowledge of interface navigation (zooming, file handling, basic drawing) is essential to keep pace.

What do I need to bring?

Bring a laptop with the free Fusion 360 Personal License installed, a mouse (mandatory), and a charger. We'll send a setup checklist before the course.

Will I design a real, buildable guitar?

Yes — unless your concept is wildly experimental, you'll leave with a buildable instrument plan. If you're designing a playable solidbody with standard geometry, we’ll help make sure it's technically coherent and production-ready.

Can I design something really unusual or ergonomic?

Yes — with limits. If your concept pushes boundaries, we’ll work with you to maintain structural integrity and coherence. We don’t stop creativity, but we also won’t validate shapes that can’t be built without major engineering.

Will I have time to design two instruments?

Three days is enough to build one high-quality model from scratch. If you’re fast, you might iterate or duplicate a second layout, but we focus on depth and precision over quantity.

Can I use the files for CNC or laser-cutting after the course?

Absolutely. You’ll leave with exported files (DXF, STL, PDF) that are compatible with CNC routers, laser cutters, or manual template production — ready to prototype or machine.