Price

2700€ - 3200€

*+Optional Belforti Tool Kit

3D Printed Neck Rest Offered

Who it’s for

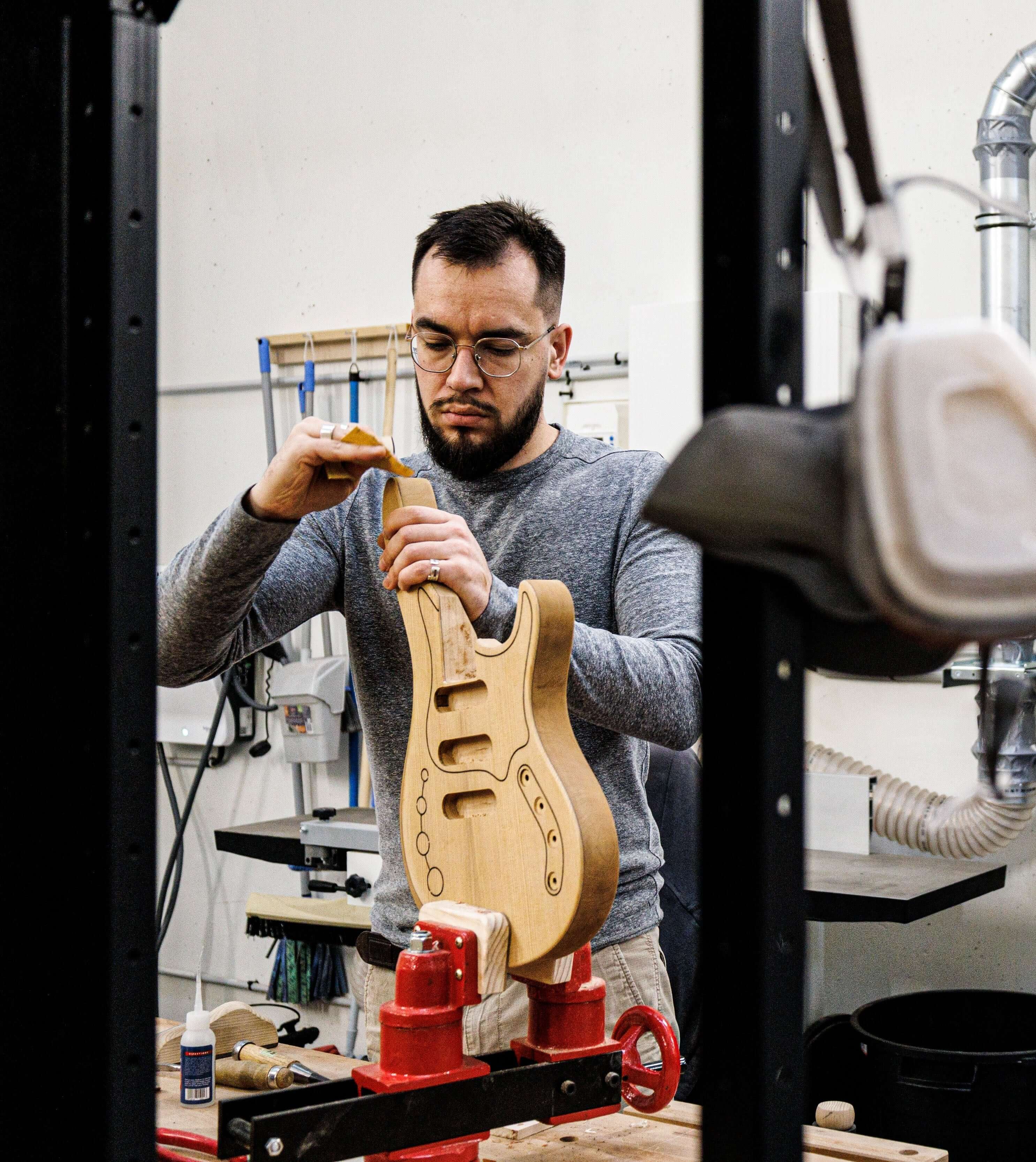

This program is designed for serious beginners, hobbyists, musicians, and aspiring luthiers alike. No prior woodworking experience is necessary — just patience, motivation, and an interest in the instrument-making process. If you’ve ever wanted to understand your guitar at a deeper level — how it plays, how it resonates, and how it's actually built — this course will take you there.

It’s also the ideal preparation for those planning to continue into the 6-Week Custom Experience, where creative design and complex builds take center stage.

What you need to bring

All essential wood, hardware, jigs and finishing materials are provided. However, participants must come prepared to work in a professional environment. You’ll need:

- Workshop-safe clothing and closed footwear

- Hearing protection (muffling earmuffs recommended)

- Your own basic lutherie tool kit (strongly recommended), or leave a deposit to borrow from the school

- Optional: your own pickups, strings, or cosmetic components (compatible with provided templates only)

A recommended tool kit is available for purchase, containing StewMac essentials — fret files, cutters, action gauge, soldering basics — enabling you to continue work beyond the course.

Duration & Group Size

15 working days — 2 to 3 participants.

Disclaimer

This is an intensive course designed for motivated participants, but successful completion of a playable instrument depends on your individual pace, precision, and focus. While the process and guidance are structured to ensure realistic outcomes, we cannot guarantee that every participant will fully complete their instrument within the 3-week timeframe. Prior experience is not required, but attention to detail, patience, and consistent daily effort are essential. Make sure you understand the physical and mental demands of this course before committing — and don’t hesitate to contact us with questions.